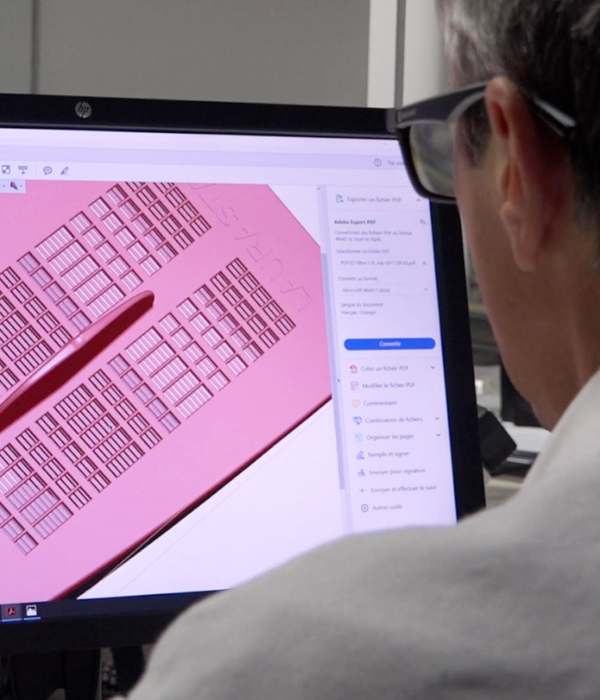

Development department

To assist you efficiently, we offer our design office team equipped with CAD.

Our development department works from the expression of your need, an idea, a sketch, a specification and offers you adapted technical solutions. It checks the technical and economic feasibility of the project, develops the drawings necessary to manufacture the means (molds, tools, machines). It accompanies you throughout the development of the design to the production. It works in project management mode.

It manages the realization of your models and prototype and realizes 3D injection simulations.

Our positioning on the luxury market imposes a high level of demand.

- Expertise

- Experience

- CAD

- Rheology

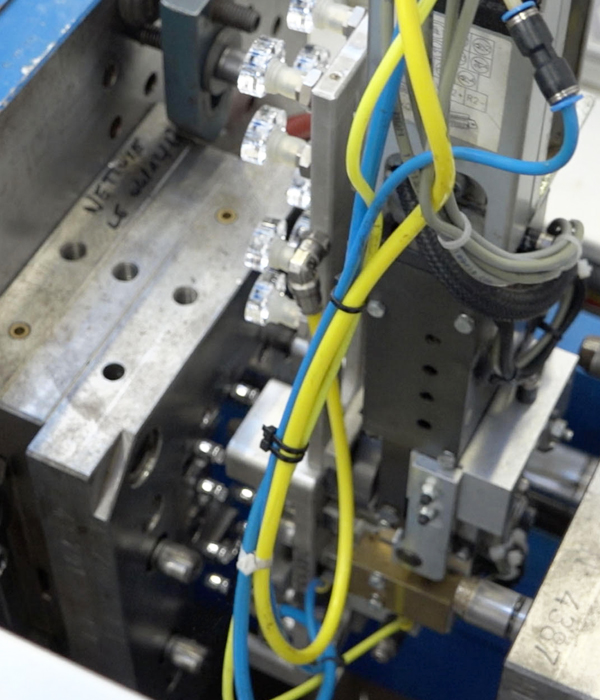

Mechanical workshop

Equipped with a mechanical workshop and the expertise of our team, we can design, modify and maintain your molds.

- Grinding

- Turning

- Wire erosion

- Sinking erosion

- Adjustment

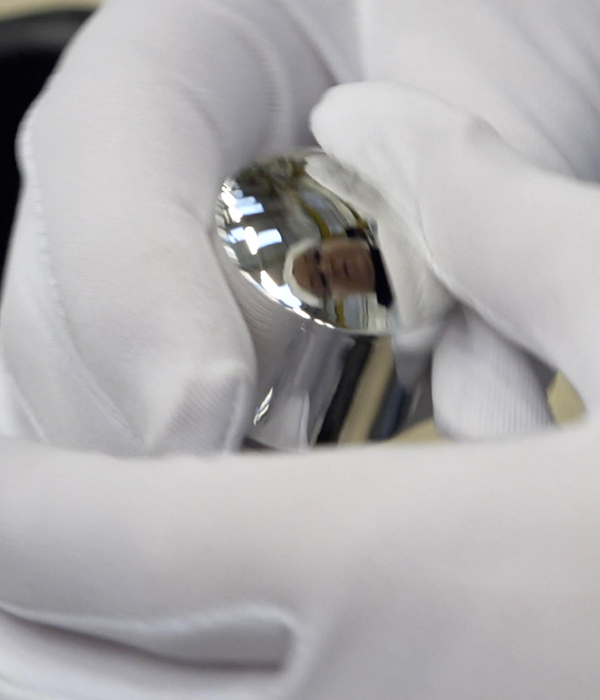

Material expertise

Our expertise guarantees you the best choices from a wide range of innovative and efficient materials to meet your needs and requirementss.

- Use crequirements (perfumes, food contact, conservation...)

- Galvanization, metallization, lacquering...)

- Decorations

- Assembly

- Various treatments

We are recognized for our know-how in transformation of specific materials:

- Surlyn, for its qualities in perfumery and cosmetics

- Copolyesters, such as Tritan, for its good chemical resistance and its absence of Bisphenol A

- Polymethacrylate of methyl (PMMA) intended for the transparent parts and of large walls thicknesses

We also offer specific materials customized to meet the various sensory requirements or related to a bio-sourced and eco-responsible design.

We also carry out permanent tests on new subjects, to bring to the project customers who wish it technical and ecological solutions.

- Bioplastiques

- Copolyester

- PMMA

- RPET

- Surlyn

Injection

Equipped with an electric machine tool of 50 to 400 tons, 100% robotized, we manufacture plastic aesthetic and technical parts in single injection or multi-material for the luxury, cosmetic perfumery, spirits, tableware but also health-care sectors

We work on small, medium or large series.

- Electric presses (50T - 400T)

- Small and medium series

- Overmolding - IMA

- Bi-material injection

Zero defect requirement

To ensure consistent quality, our production is subject to several levels of control. We guarantee the traceability of our products.

- Quality Control

- Custtomer stisfaction

- ISO 9001 certification

- Supplier, subcontractor and customer audits

Finishing / Decoration

We offer a varied range of finishes, surface treatments and decoration, adapted to the technical and aesthetic specificities of the product.

Our teams answer all your finishing requests.

Many finishing possibilities exist to give your products best rendering.

- Decorations (Silkscreen, Hot stamping, Pad printing)

- Electroplating

- Vaccum Metallization

- UV lacquering

Assembly

Our workshops are equipped with versatile automatic machines to assemble your parts for medium or large series.

Manual assembly is also possible according to your needs.

We also have the ability to rmanage the development of complex and specific machines.

Our development department knows how to respond to this demand, by its technicality and experience.

- Standard and specific assembly machines

- Laser cutting

- Ultrasonic welding